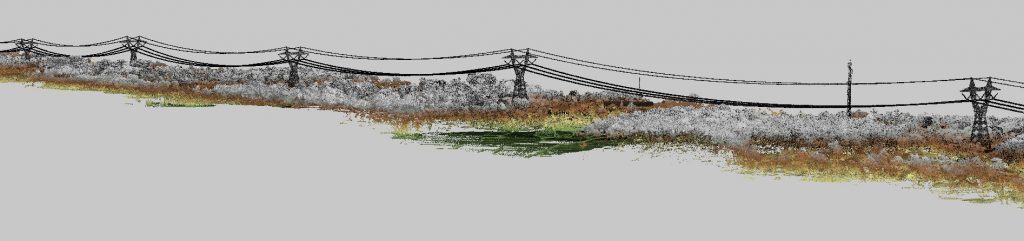

Indonesia has an extremely favorable climate for vegetation development: abundant sun, high humidity, and regular rains, so the landscape can change very fast. This is why the National electricity distributor, PLN, must regularly inspect the high voltage lines, in order to do proactive maintenance to avoid any contact between vegetation and the catenaries. The power line inspection in Indonesia can quickly become a challenge due to the topography: changing and inaccessible relief, or due to the configuration of the land: rice fields, swamps, dense jungle etc … making the work of inspectors on the ground almost impossible in some cases. Lidar inspection by drone is therefore becoming a major tool for accurately and “easily” recording the development of vegetation and taking the necessary measures to avoid any interruption of service or even disaster.

Client

Direct client : HaloRobotic & Aerodyne

Final Client : PLN

WHAT WE DID

3D LiDAR asset inspection by drone / UAV 3D mapping

Lidar power line inspection can accurately measure the distance from overhead lines to surrounding vegetation. Thanks to analysis software, it is possible to generate reports and alerts according to the specified safety distances. It is also possible to have warnings if a tree is considered a risk because of its size, even if it is far from the lines, but which if dropped, could create damage to the network.

For this Mission we had the honor to work in collaboration with HaloRobotic and Aérodyne and thus offer them our data acquisition services by lidar.

The mission, or rather, the missions, took place in the regions of Sukabumi and Serang, on the island of java (about 3 hours from Jakarta). The main challenge was the weather, which was very unstable: sudden torrential rain, fog on the top of the hills. The second challenge was the relief, and mainly in the Sukabumi region, which is made up of small valley, mainly famous for these tea tree plantations.

Our team of 4 people: 1 drone operator and assistant, 1 project supervisor and 1 driver carried out the data acquisition during about 4 days in the field (not counting the mobilization time between the two sites). With an average output of 12km per day, we were able to deliver the data to the customer very quickly, which compared to traditional manual readings, would have taken weeks and probably would not have provided as much information on the condition of the lines.

The results are breathtaking! The level of detail of the Riegl Minivux-uav1 is sensational and allows you to see the smallest branches that could touch the lines. The catenaries are perfectly captured, without any gaps or “holes” in the data. The precision of the laser makes it possible to have a really fine reading of the cables and an adjustment to the centimeter between the different “stripes”. For data processing, it only took us a day to export the entire project and provide the data to our partners for report generation. We are very proud to have made this mission successful and are happy to see the satisfaction of our customers. And you, will you be the next to call on us?